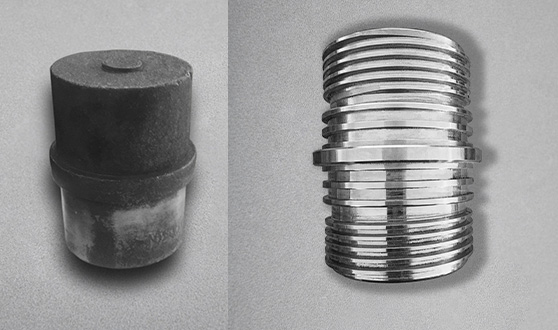

Forging is a crucial process determining the strength of the manufactured parts. It changes the metal through compression and hot forging is a technique used to harden the metal, providing it with ductility and yield strength. The process plays a crucial role in affecting the tolerance of metal components.

Saturn Oil Tools is the home of economical forging processes. By using hot forging, we aim at reducing material cost and machining cycle time, thereby reducing the overall costs and providing affordable components. While engineers focus on improving the overall strength of the products, the modern hot forging setup accelerates the machining cycle to deliver products faster. Our quality checks ensure that we deliver products that last longer, engineered to provide the best quality and maximum strength. Our automated processes and Computer Numerical Control have helped us scale our forging operations, reduce costs and increase efficiency.

- Hot forging (400 tonnes, 200 tonnes)

- Heat Treatment (Pit-type and continuous)

- CNC machining

- Hi-tech lab